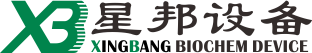

This firm originally adopted a perforated annulus air sparger in 200m3 vitamin fermentors, as shown in Fig.4. And it was equipped with Lightnin stirring system: 3-leaf impellers in the upper region, and a 5-leaf semicircle turbine at the bottom.

Existing problem

Perforated tube was too simple to achieve strong gas dispersion, thus DO level in fermentors was inadequate. Looking into observation window, one could spot huge bubbles and unstable liquid level, which indicated that oxygen was not well utilized.

Implementation of Vitamin fermentor modification

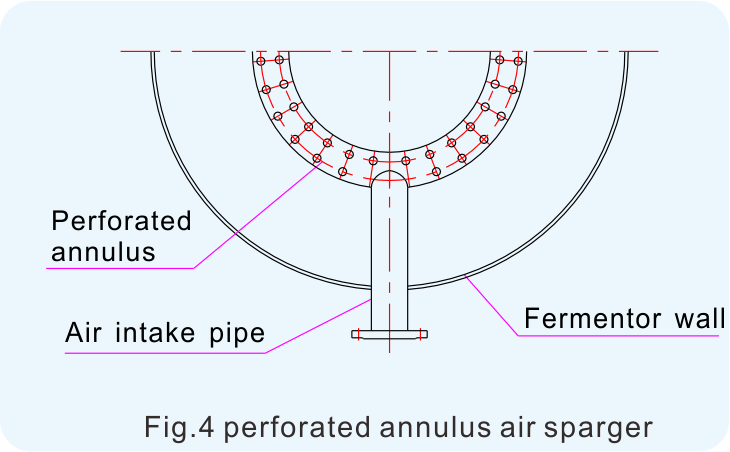

(1) Replace the perforated annulus sparger with vortex G-L miser. In this case, the mixer had been specially design to give space for original bottom bearing.

(2) Reduce stirrer shaft speed.

(3) First batch showed DO level is excessive even when lowered stirrer shaft speed, which was unfavorable to yields. After unloading 3 leaves from the 6-leaf turbine, satisfactory results obtained with proper adjustment.

Modification plan is shown in Fig.5. Construction photo is shown in Fig.6.

Vitamin Fermentor modification results:

(1) DO level improved dramatically。

(2) Stirrer shaft current dropped by 5%~30%.

(3) Stable liquid level, no huge bubbles.

(4) Antifoam use reduced by 1/3.

(5) Product yield improved remarkably.