Fermentation industry in China started late than other industries, widely used is fixed tube plate heat exchanger. With the consistent development of fermentation production technology, its performance has been difficult to meet the needs of production and energy saving. CKL, CKR series of new type air heat exchanger by our company is very suitable for features of the fermentation industry, play an important role in the system energy saving in the factory. This new type heat exchanger has three patents of People’s Republic of China.

Technical Background

Features

Use aluminum fins to strengthen heat transfer, composite finned tube heat exchanger, increase the heat transfer area, to reduce the cost

Low air flow speed in the shell, low pressure loss

Multi-tube configuration, able to deploy several process fluids with different temperatures

In comparison with fin heat exchanger, low heat stress deformation, not easy to get damaged, safe to use

Multi-tube unit arrangement, easy to drain and clean without a stop

Great performance in water-saving, electricity-saving and vapor-saving

Pressure balance inside and outside the tube, actual pressure balance operation, so eliminate the leakage risk and ensure stable and energy-saving production.

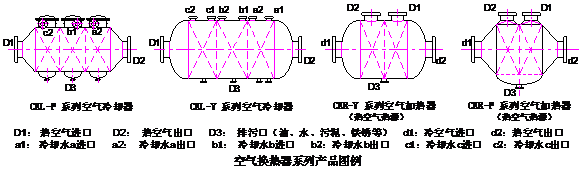

Models